Description

Dimlux are experts in designing the best possible optics with the highest efficiency and uniformity for its fixtures to meet the most demanding lighting requirements in the most complicated grow areas. The patented “broken” lens design ensures the highest possible efficiency in the market. The innovative and unique modular technology ensures highly efficient tailored LED lighting in vertical grow farms and a stable cultivation climate.

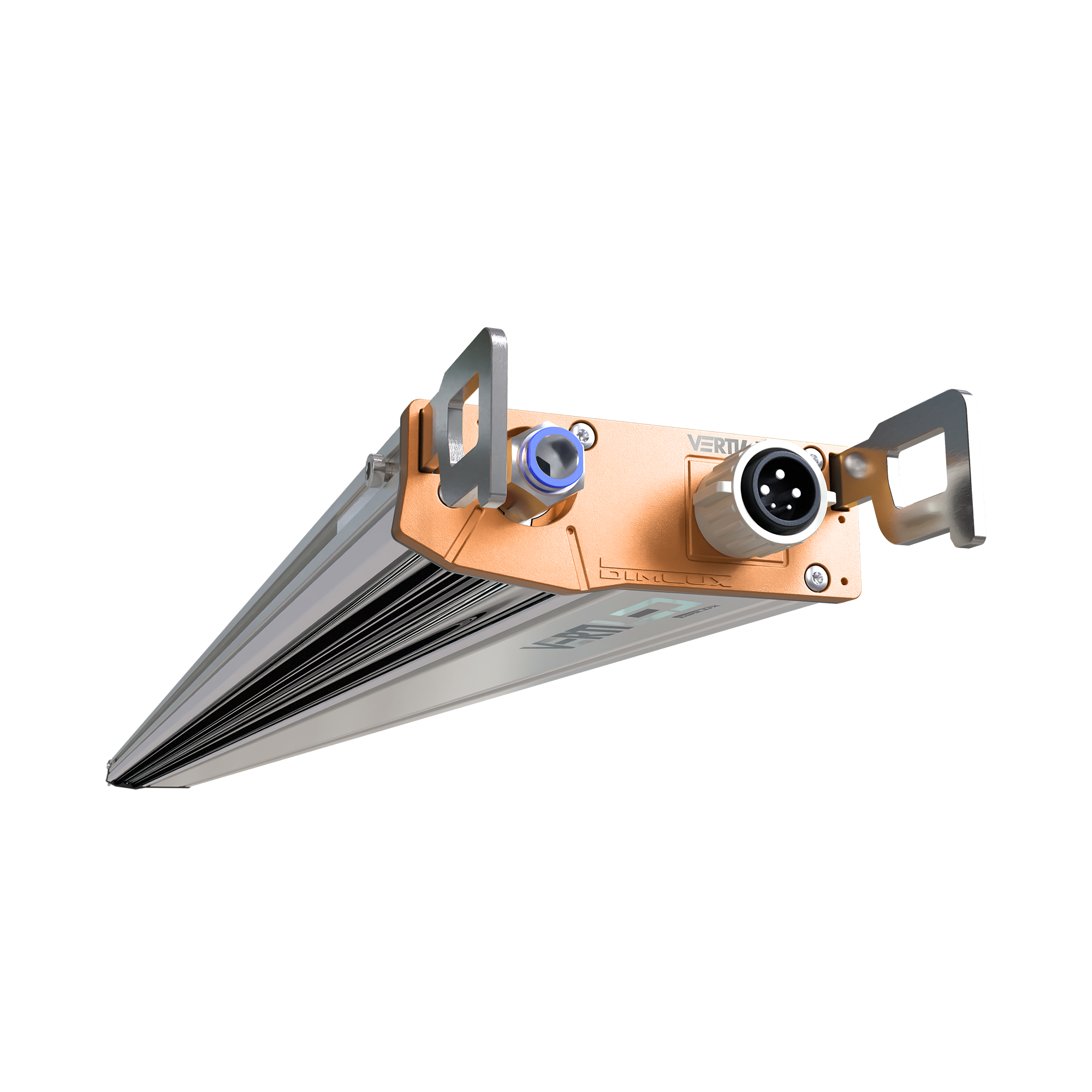

The new vertiLED vertical grow farm fixture is specifically designed to distribute light uniformly, even with extremely little distance between fixture and crop. The vertiLED can be used for close-to-crop applications such as vertical grow systems and growrack systems in a grow farm.

A high “FULL WIDTH” fixture-to-grow-bed UNIFORMITY and efficiency

The unique angled position and asymmetric high-precision optics distributes the light uniformly over the full width of the grow bed. With conventional vertical growing lighting systems, light decreases towards the sides of the grow bed, and they don’t prevent light falling outside of the grow bed. This is inherent to symmetrical light designs. The vertiLED overcomes this limitation by using an asymmetrical design of the secondary optics. The optics amplify the light that falls on the grow bed and attenuates the light that falls outside of the grow bed. Because of this, vertiLED offers the highest fixture-to-grow-bed light efficiency in the market.

The patented “broken” lens design ensures the highest possible efficiency

Dimlux are experts in designing the best possible optics with the highest efficiency and uniformity for its fixtures to meet the most demanding lighting requirements in the most complicated grow areas. The patented “broken” lens design ensures the highest possible efficiency in the market. The innovative and unique modular technology ensures highly efficient tailored LED lighting in vertical grow farms and a stable cultivation climate.

The vertiLED overcomes this limitation by using an asymmetrical design of the secondary optics. The optics amplify the light that falls on the grow bed and attenuates the light that falls outside of the grow bed. Because of this, vertiLED offers the highest fixture-to-grow-bed light efficiency in the market.

Specifications

|

EXAMPLE 1 |

|

|

Channel 1 |

White 4000K – 300W – 800 µmol/s |

|

Channel 2 |

Deep Red – 180W + Far-red – 20W – 610 µmol/s |

|

|

|

|

EXAMPLE 2 |

|

|

Channel 1 |

White 455nm peak 66W 155µmol/s 2.31µmol/J |

|

Channel 2 |

Deep Red 660nm 259W 940µmol/s 3.62µmol/J |

|

Channel 3

|

Far Red 730nm 33W 86mol/s 2.6µmol/J |

|

Channel 4 |

Blue 455nm 66W 152µmol/s 2.3µmol/JPatented Wide Beam Ultra High Transmittance Lens |

|

|

|

|

COLORS |

|

|

UV-A (broadband or narrow-band) White (435nm blue peak), White (455nm blue peak), Blue, Lime, Red, Deep Red, Far-red. White options can have different color temperatures. |

|

|

|

|

|

SPECIFICATIONS |

|

|

Voltage: |

100-300V

|

|

Pipe thread: |

G 3/8” |

|

IP Rating:

|

IP66

|

|

Weight:

|

Max. 9.5kg

|

|

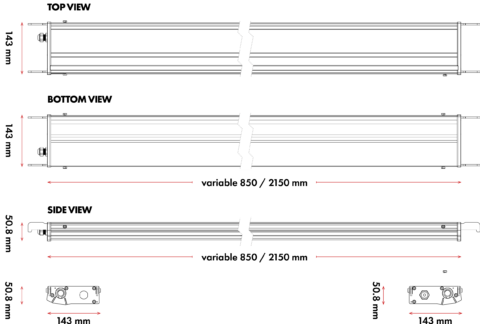

Measurements:

|

750 — 2200mm x 143mm x 50.8mm

|

|

Warranty:

|

5 Years |